micronozzles

Micron-size Features,

Sub-micron Accuracy.

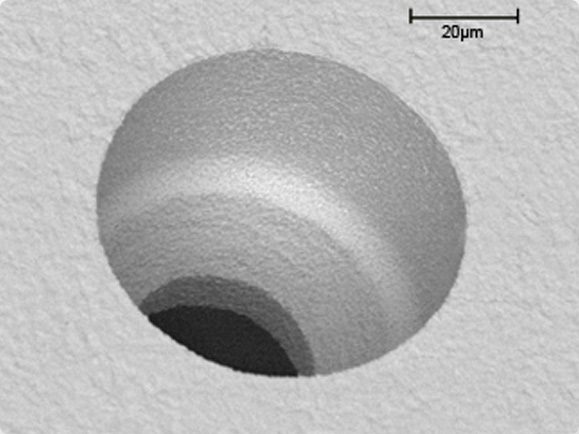

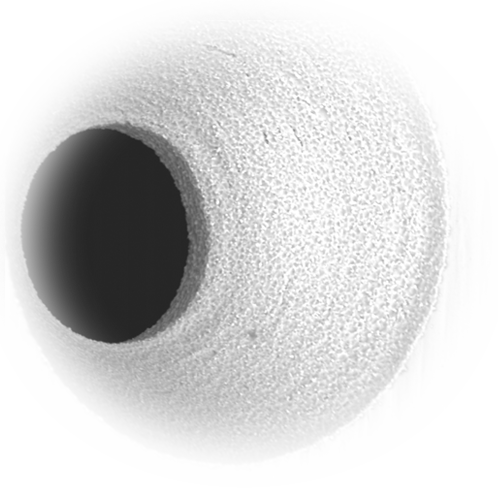

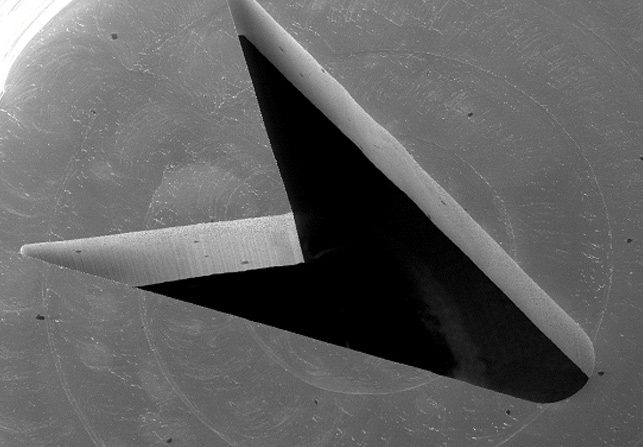

Our micronozzle fabrication process was developed to assist a two-phase drop-impingement cooling system for space station electronics. With 10+ micron diameters and sub-micron accuracy, our micro-EDM group has produced over 200 million custom-contoured micronozzles and nozzles plates for jetting applications in industrial inkjet, medical, and scientific markets for nearly 30 years.

Mikros Micronozzle Capabilities:

- Nozzle substrates from any electrically conductive material, typically stainless steel

- Diameters ranging from 10 to 175 microns with sub-micron accuracy

- Positional accuracy to less than a micron

- Shapes in any profile of constant or descending diameter

- Foil Aspect ratios as low as 10%

- Surface finishes to Ra=2 micro-inches or less

- ISO-9001-2015 Certified Design and Manufacturing

Micronozzle Services:

- Nozzle Design: Collaborate with our design team on optimal nozzle contouring or let us build-to-print

- Substrate Fabrication: Drill on precision foil or on complex, diffusion-bonded base structures

- Nozzle Drilling: Optimize your nozzle plate design with single-nozzles or a large nozzle array

- Precision Inspection: Verify critical features with the latest automated optical inspection technology

- Laser Marking: Serialize parts with fixed or variable data in alpha-numeric or barcode/QR

- Ultrasonic Cleaning: Receive nozzles plates packaged and clean room ready