Performance

High Effectiveness, High Value

With core 1 thermal resistances as low as 0.02 C-cm2/W, low pressure drop and configurable, affordable designs, Mikros microchannels are among the most effective liquid-cooling solutions available. Below are key performance metrics and features to evaluate if a Mikros liquid cold plate is right for your system.

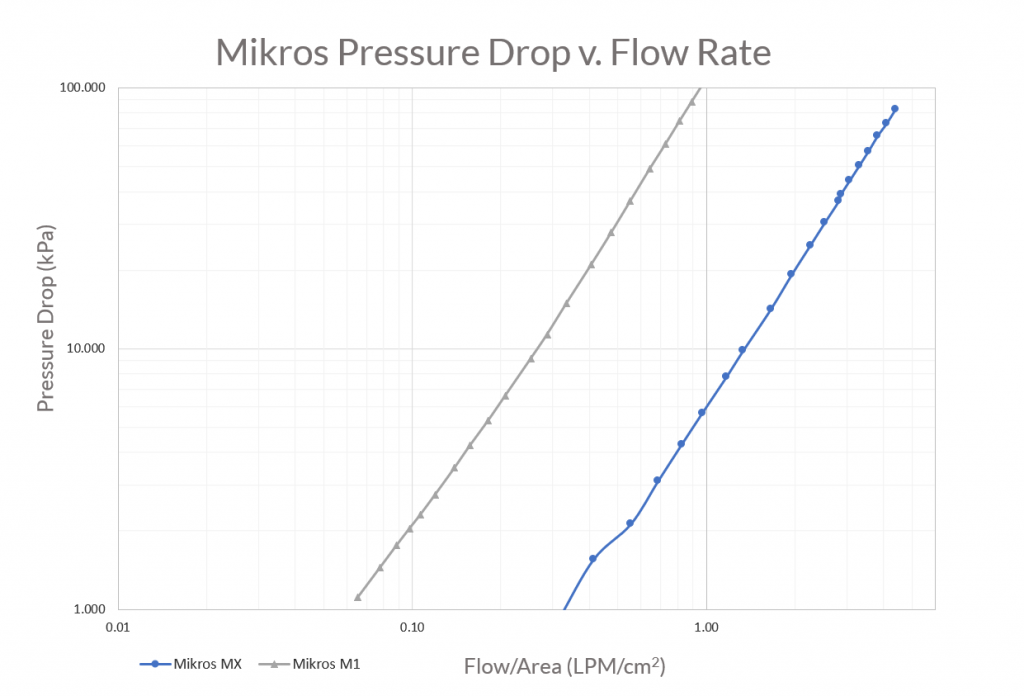

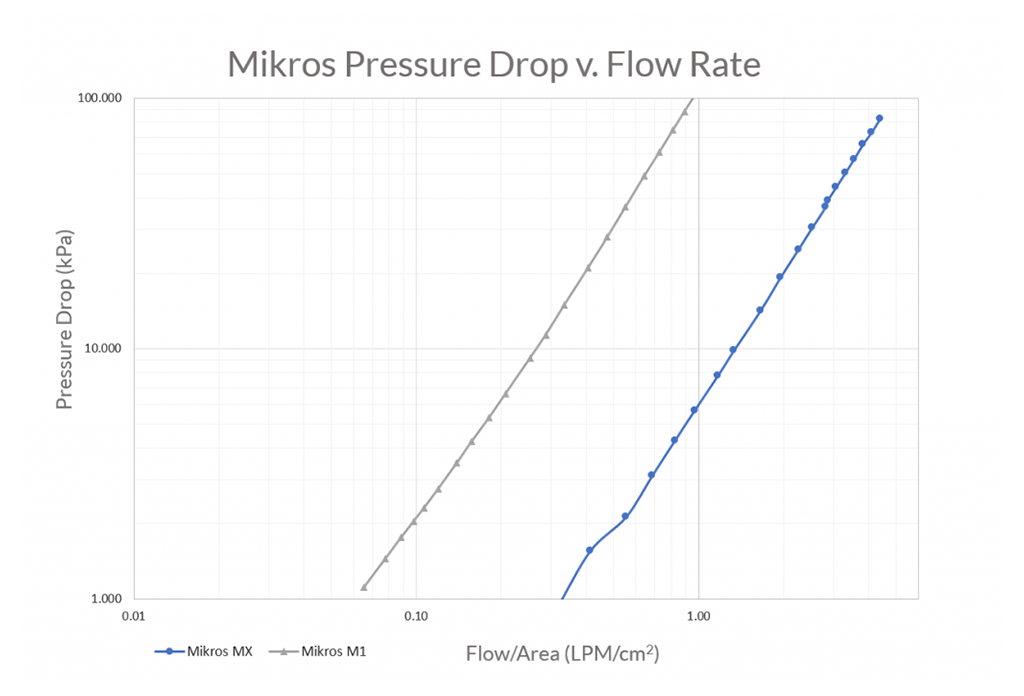

Pressure v. Flow

Below are key performance metrics and features to evaluate if a Mikros liquid cold plate is right for your system. With core1 thermal resistances as low as 0.02 C-cm2/W, low pressure drop and configurable, affordable designs, Mikros microchannels are among the most effective liquid-cooling solutions available.

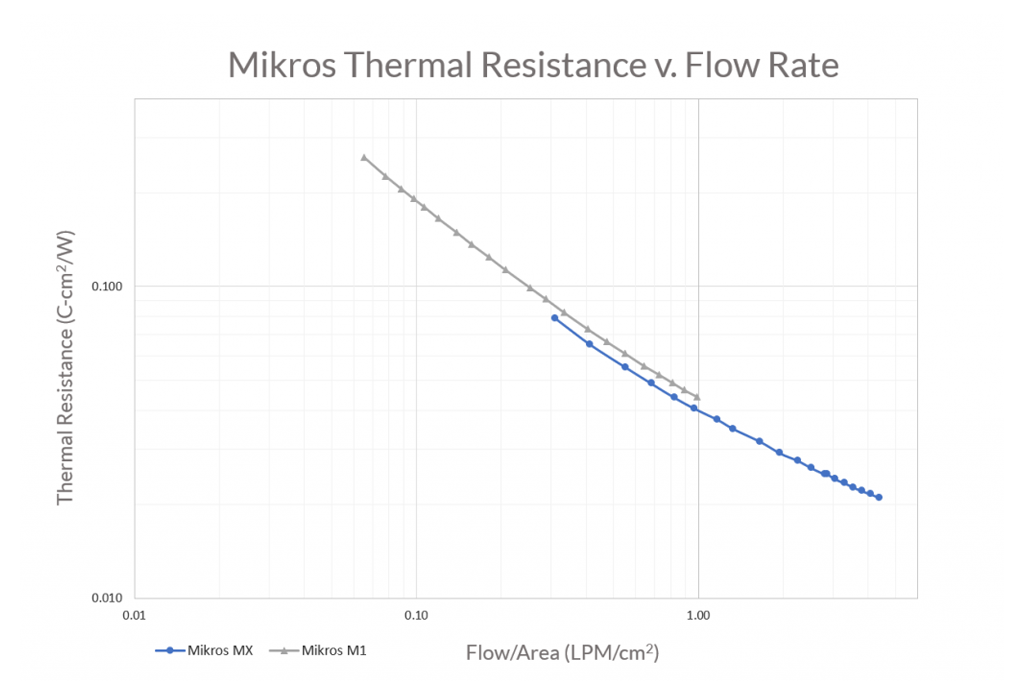

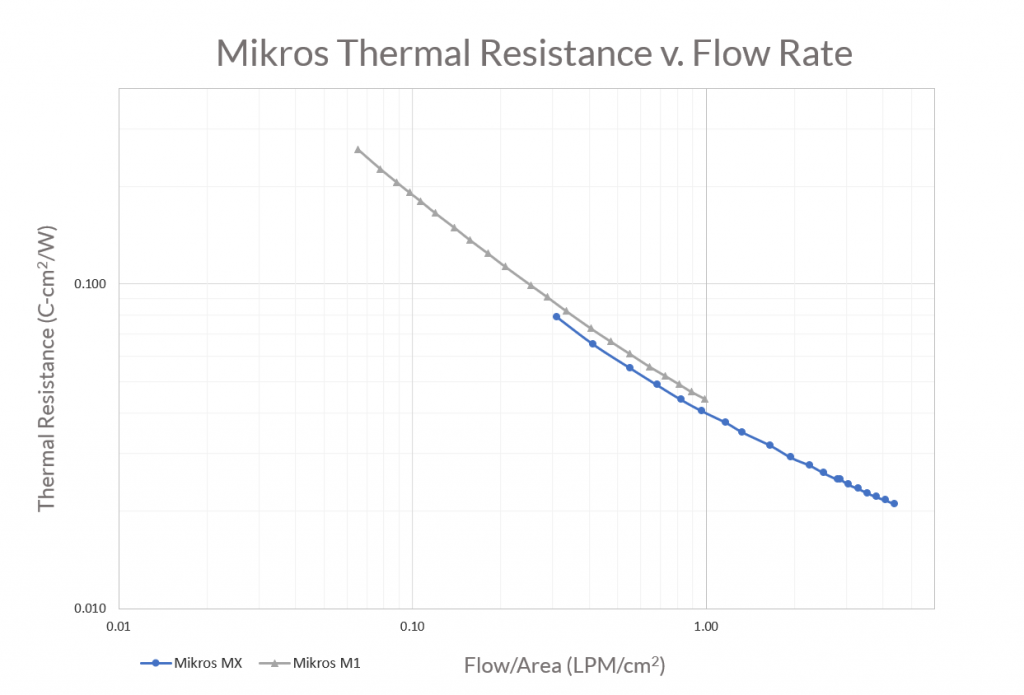

Resistance v. Flow

With core1 thermal resistances as low as 0.02 C-cm2/W. Below are key performance metrics and features to evaluate if a Mikros liquid cold plate is right for your system.

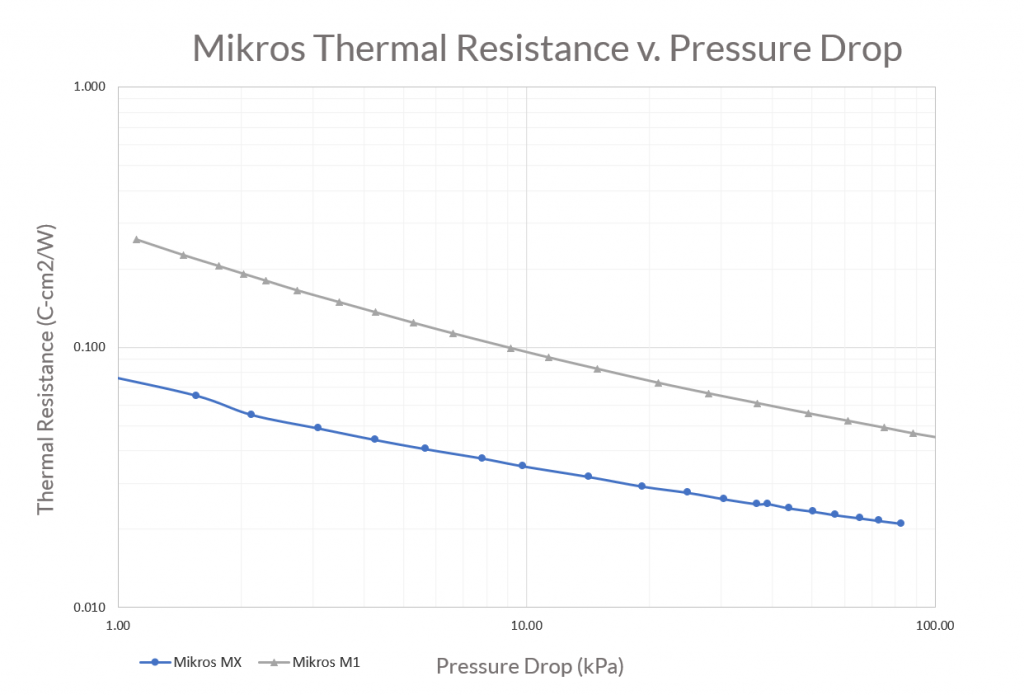

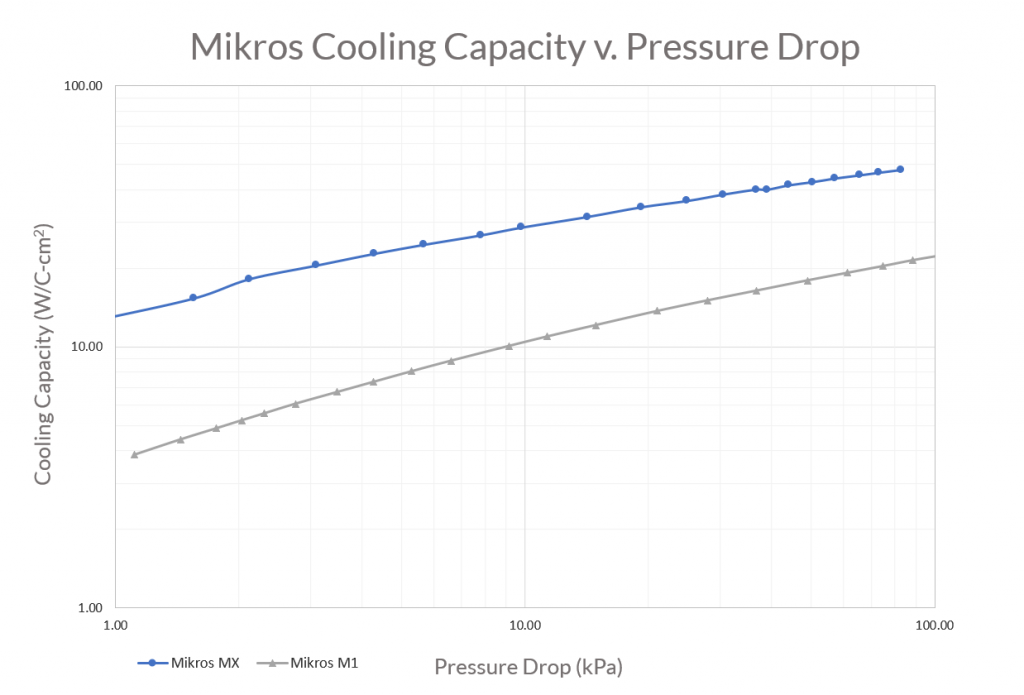

Resistance v. Pressure Drop

Below are key performance metrics and features to evaluate if a Mikros liquid cold plate is right for your system.

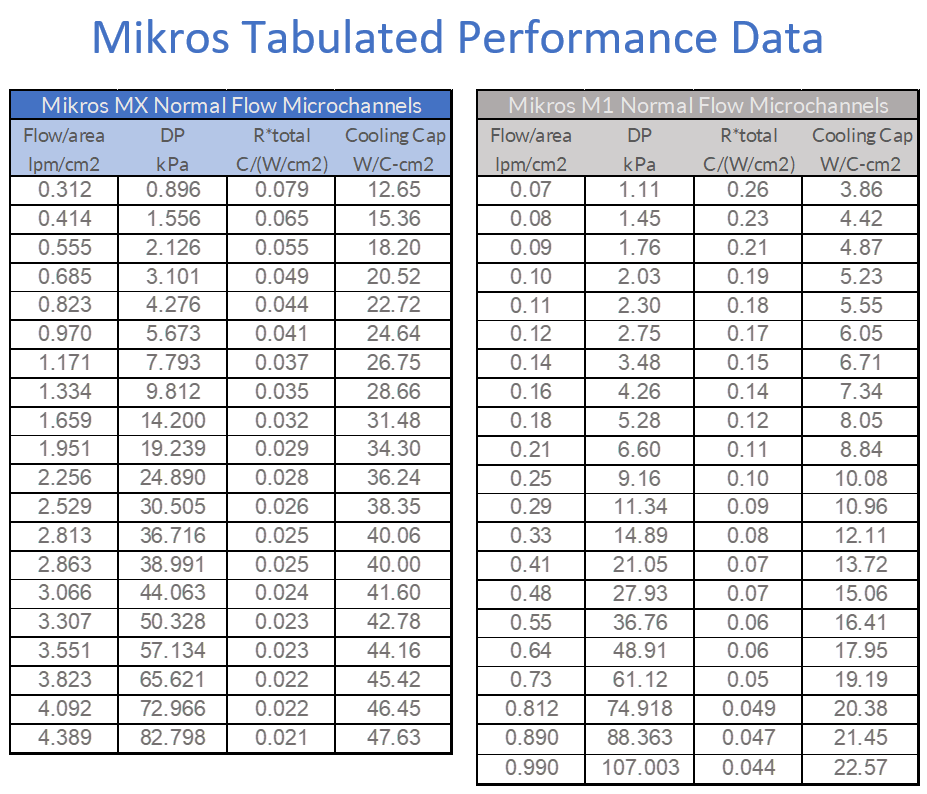

Tabulated Performance Data

With core1 thermal resistances as low as 0.02 C-cm2/W, low pressure drop and configurable, affordable designs, Mikros microchannels are among the most effective liquid-cooling solutions available.

Low Thermal Resistance

The thermal resistance of Mikros cold plates approaches the lower theoretical limit over a wide range of flows. Our microchannel cold plate matrices can achieve thermal resistances 1-2 orders of magnitude lower than swaged-tube and pin-fin cold plates with comparable pressure drops.

Low Pressure Drop

The pressure drop of Mikros microchannel and minichannel cold plates range from 5-35 kPa (1-5 psi). Our patented Normal Flow™ design dramatically reduces pressure drop and provides thermal resistances up to 2 orders of magnitude lower than cold plates at equal pressure drops.

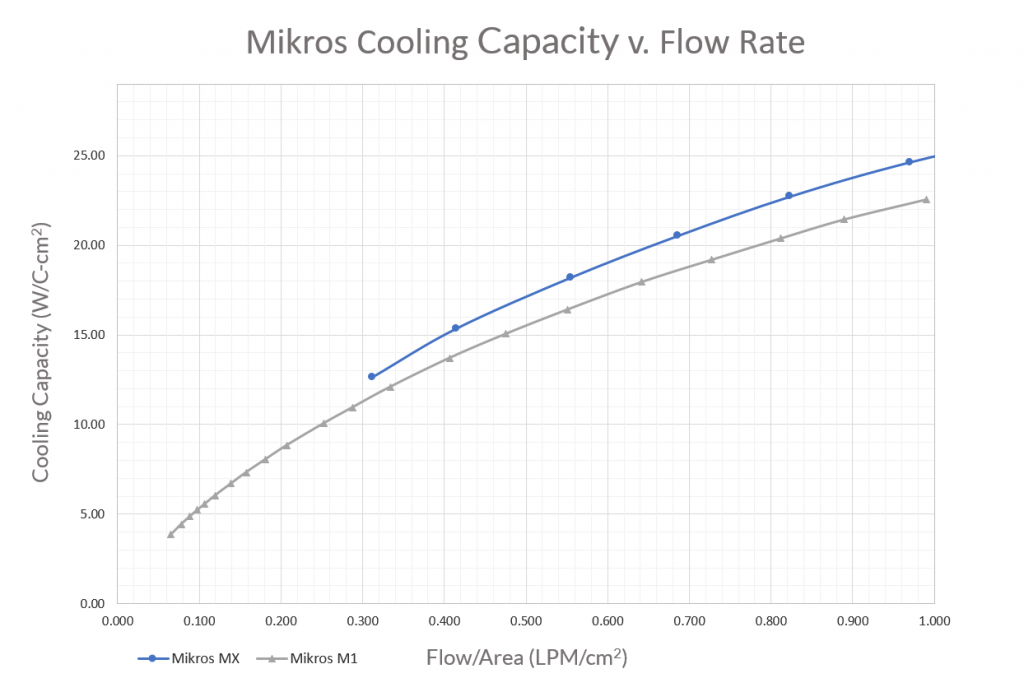

High Cooling Value

As cooling requirements become more stringent, the cost-per-Watt of Mikros’ microchannel cooling quickly becomes less than cold plates with lower effectiveness. Mikros’ high heat transfer capacity can also provide savings in reduced pump and peripheral component size and count.

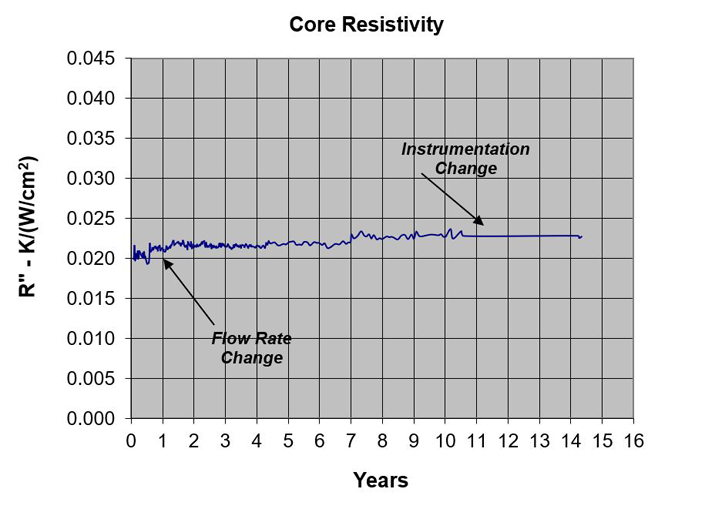

High Reliability

Mikros cold plates have shown no change in core thermal resistance for nearly 15 years in our endurance test facility using filtered water with corrosion inhibitor and algaecide. Over that time, our clients have incorporated tens of thousands of complex Mikros microchannel cold plates in high-power computing systems where reliability is critical.

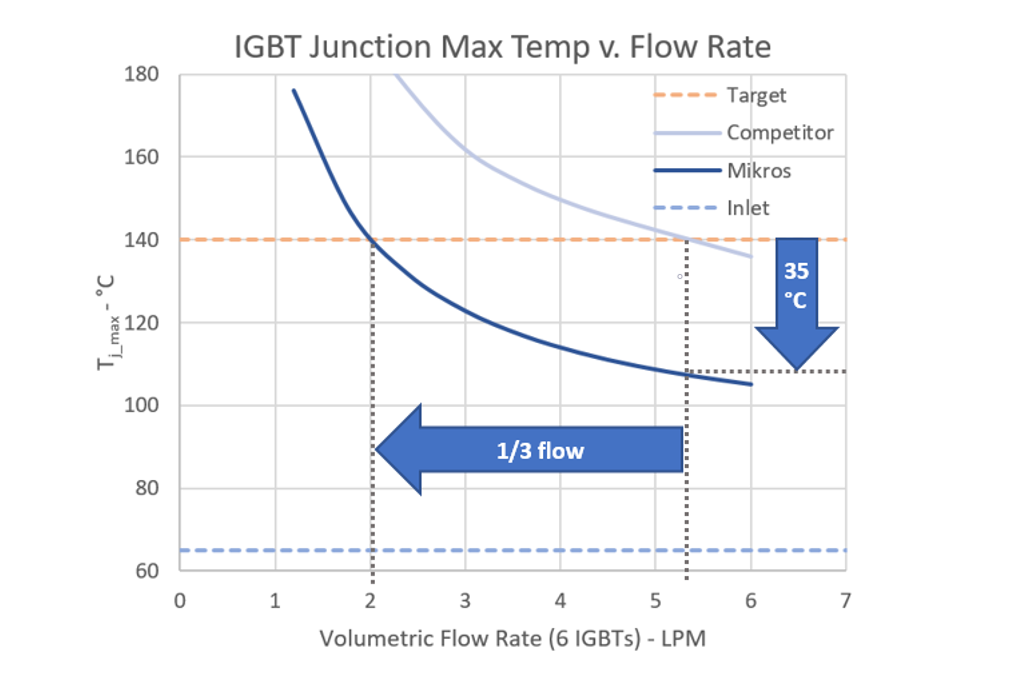

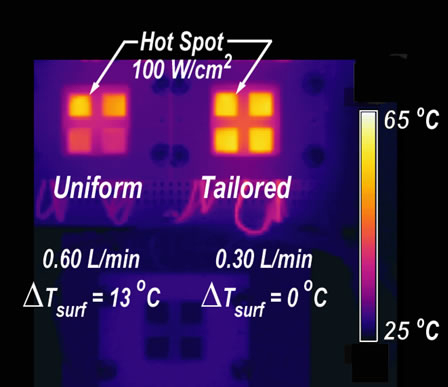

Tailored Cooling

Mikros Normal Flow™ microchannels distribute inlet temperature coolant over the entire heated surface. By directing larger flows to those areas requiring higher cooling capacity, the local thermal resistance can be tailored to mitigate “hot spots,” eliminating temperature gradients and reducing the total coolant flow requirements.

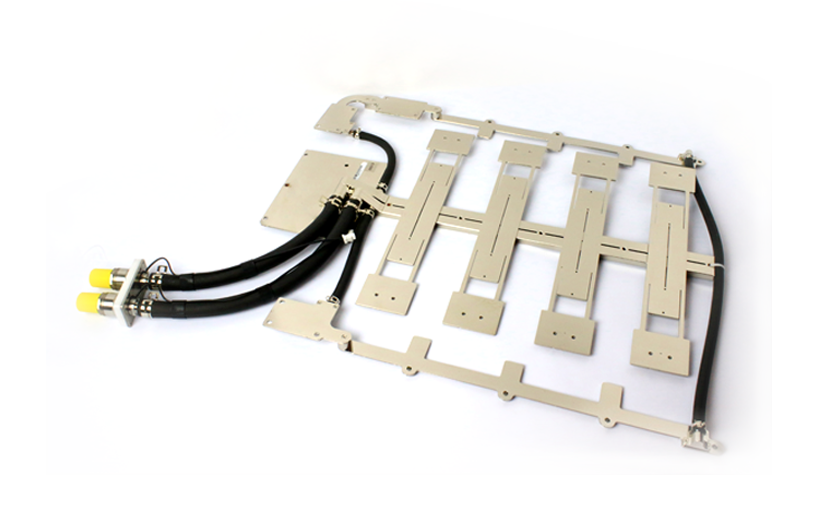

Adaptable Design

Mikros’ Normal Flow™ microchannels can be fabricated in a wide array of complex topologies. Our cold plates range from 4x4mm to 300x500mm assemblies with many cooling areas. We design custom features to accommodate component height and tilt tolerances, CTE-matching, TIM force requirements and non-planar cooling areas.

1 Thermal Resistance Definitions

- Total Thermal Resistance:

- Core Thermal Resistance: Rcore =

- Flow Thermal Resistance: Rflow = A/

As the flow rate increases, flow resistance decreases, and the total thermal resistance approaches the core resistance.