Micronozzle Features

In the late 1980s, a thermal management project for NASA required Mikros to develop and produce micronozzles with customized internal contouring and high positional accuracy.

From that success, our proprietary micro-EDM manufacturing process has evolved over 30 years to produce hundreds of millions of micronozzles in arrays and assemblies with micron-level features and sub-micron accuracy.

We can provide our nozzle assemblies with full inspection data to assure our clients that our nozzles will meet their application demands.

Several features make Mikros’ micronozzle technology a strong candidate for your microfluidic jetting application:

Internal Contouring

Nozzle shape and design play an important role in controlling the trajectory of a fluid droplet. Mikros nozzles can be formed with a range of entrance and exit diameters, internal bell or angled walls, and straight descending segments. Depending on the fluid being propelled and the actuator used, the internal shape of the nozzle can be tweaked relatively easily to provide optimal droplet placement.

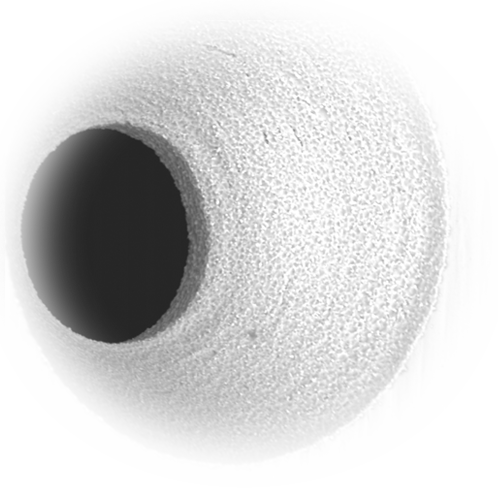

Micronozzle Concentricity

In addition to the internal profile, the concentricity of a nozzle, or its straightness throughout the substrate, is an important aspect in many jetting applications. Poor concentricity leads to droplets that land outside of their desired location. Mikros’ proprietary micro-EDM process provides exquisite concentricity profiles, often better than etched nozzles can provide.

Sub-Micron Positional Accuracy

In addition to micron-level features, including 10-20+ micron exit diameters. Our micro-EDM process can provide sub-micron accuracy on nozzle placement and wall profile to ensure optimal jetting performance over time.

Internal Surface Finish

The internal surface finish of our micro-EDM nozzles can also be adjusted to provide a rougher or smoother surface finish. Depending on the viscosity and surface tension of the fluid to be jetted, adjusting the surface finish can help increase the efficiency and effectiveness of the jetting system and provide a superior result.

Get in Touch With Us to Learn More

Mikros micronozzles can improve the performance and reliability of your jetting, dispensing and cooling applications. If a nozzle or nozzle array is a part of your system, we would love to see if Mikros can help you achieve your design goals.

For more information about our micronozzles and liquid cooling solutions, contact us via form submission or give us a call!